V&V Walsh

Streamlining operations and enhancing efficiency

V&V Walsh, a family-owned Australian company, holds a significant presence in the meat processing and export sector. Based in Western Australia, their operations are centred around processing and exporting top-quality beef and lamb products. As a key player in Australia’s meat industry, V&V Walsh is renowned for its commitment to producing premium meat products for both the domestic and international markets.

In late 2022 V&V Walsh engaged ThreeSixty review their current processing and distribution operations and based on the outcomes of this review provide recommendations and execute the RFP process, through to the evaluation and selection of a preferred vendor.

Challenge

One of the key challenges was identifying a suitable WMS that aligned with existing requirements and IT designs. The search for a seamlessly integrable WMS in accordance with current requirements was pivotal. The chosen WMS had to effectively integrate within the present IT solution design. Overcoming these challenges, incumbent MHE vendors worked to ensure the feasibility of their assumptions and designs. Through meticulous workshop discussions, the conveyor design was tailored to address technical and operational hurdles, resulting in an optimised carton workflow logic that fulfilled the high-level requirements of all stakeholders. Concurrently the V&V Walsh’s regional location provided challenges, and ultimately the successful vendor had an office in Perth.

Solution

ThreeSixty conducted an in-depth review of current processing and distribution operations on-site. V&V Walsh’s existing customer and business rules were examined, alongside an analysis of systems architecture. ThreeSixty facilitated collaborative workshops involving IT, distribution, and production teams to align requirements for future functionality. This phase resulted in an agreed business requirements document.

This review led to the design of future production and distribution operations. Discussions with key vendors (Dematic, Milmeq, Vector) clarified integration expectations. The impact on customers was assessed, leading to the creation of the WMS requirements document, which was utilised as part of the RFP process.

ThreeSixty developed an RFP with specific selection criteria to assess potential vendors on their ability to meet requirements. The evaluation process included shortlisting WMS vendors and detailed evaluations ensured participants and offerings were thoroughly reviewed against V&V Walsh’s specific requirements in order to choose the best suited WMS partner.

Outcome

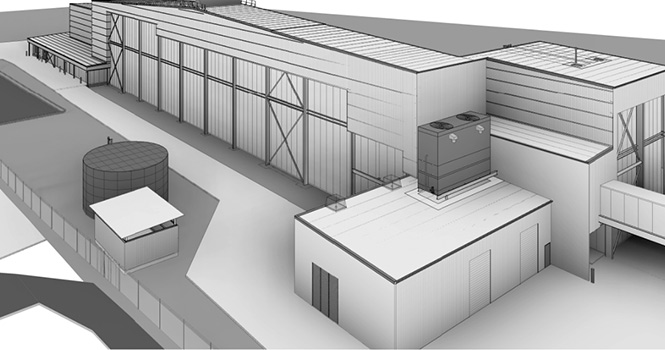

ThreeSixty reviewed multiple WMS vendors, based on this review ThreeSixty’s recommendation was to deploy a cloud-based solution, the strategic establishment of a new Distribution Centre played a central role in internalising the complete end-to-end supply chain. This transition was pivotal as the warehousing services, including freezing, export, and distribution, were previously outsourced to 3PLs.